Proven technology for continuous removal of floating solids and clean water

The Challenge

Settling tanks are used in the treatment of storm water, combined water and wastewater in industrial as well as communal areas.

They are installed for the protection of environment or for the treatment of industrial effluent. The best known facilities are oil separators. Settling tanks are specially designed by expert engineers for each application to achieve optimal retention of pollution at low flow rates and calculated maximum flow rates.

The System

The separation of light density materials basically occurs towards the water surface; heavier solid matter settles on the tank floor. The transition zones from sediment to clean water and from clean water to floating solids are “mist zones” prone to problems.

Procedure 1

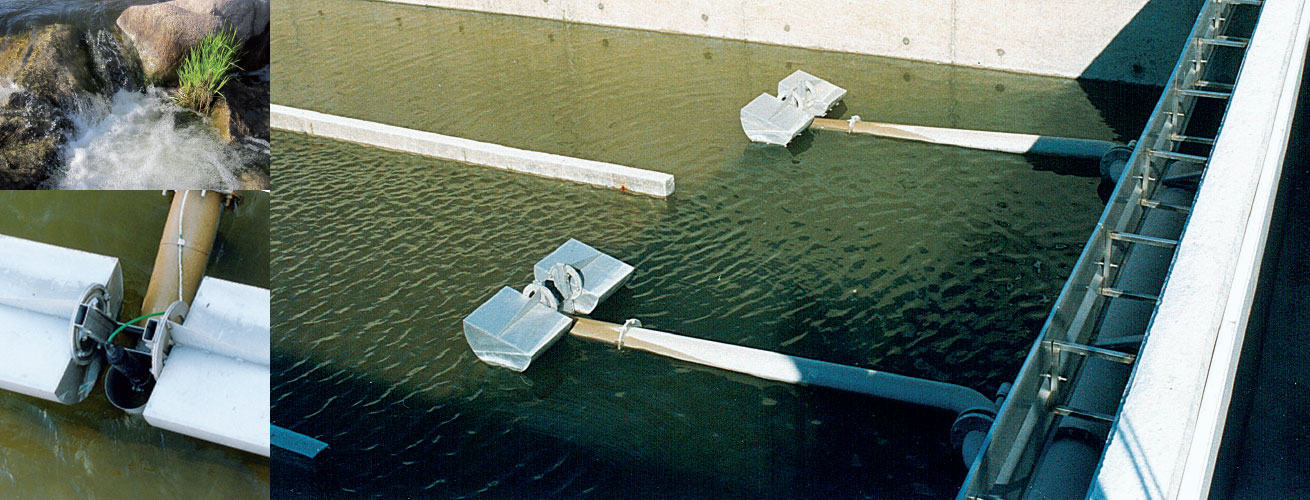

The HydroSurf Skimmer draws the floating solids and light density matter from the water surface for treatment. Simultaneously, an ElectroSlide® positioned above the sediment zone conducts the clean water, depending on turbidity, out of the tank into the receiving waters. After emptying, the tank floor is cleaned with the HydroSelf® Wave Flush and the pollution pumped away for treatment.

Procedure 2

The HydroSurf Decanter with integrated turbidity measurement drains away the clean water under the floating solids zone. Either through gravity or by means of a pump, it conducts the clean water into the receiving waters. If the sediment zone is reached when the water level falls, the HydroSurf Decanter is closed. A second motor slide is opened or a pump is used for cleaning the tank. Floating solids and sediments are washed away to the treatment plant by the HydroSelf® Wave Flush.

The Product

The HydroSurf Skimmer and Decanter are manufactured completely of stainless steel. They are equipped with a wear-free, smooth-running and water-tight swivel joint. One 90° elbow is connected to the drainage pipe, the other 90° elbow to the outlet pipe. To enable the HydroSurf to work continuously at different water levels, adjustable twin floats (angle, immersion depth) are positioned at the inlet. The buoyancy within the float can cope with the loading conditions under full load. The inlet heads can be manufactured on request with inlet grid, scum board or with immersion fittings and turbidity detector. The HydroSurf Skimmer and Decanter can operate impound heights of approx. 2.50 m to 8.00m. The discharge values lie between 5 l/s (DN100) and 200 l/s (DN400).

Steinhardt GmbH offers design support and, if required, delivery includes complete units with electric flow regulator, turbidity detectors, tank cleaning and automation.

Range of Application

- recovery of operating materials

- for treatment of process water

- before SSO’s into receiving waters

- before soil filters

- before infiltrations