Continuous retention of floatables – no external energy, no moving parts –

The Challenge

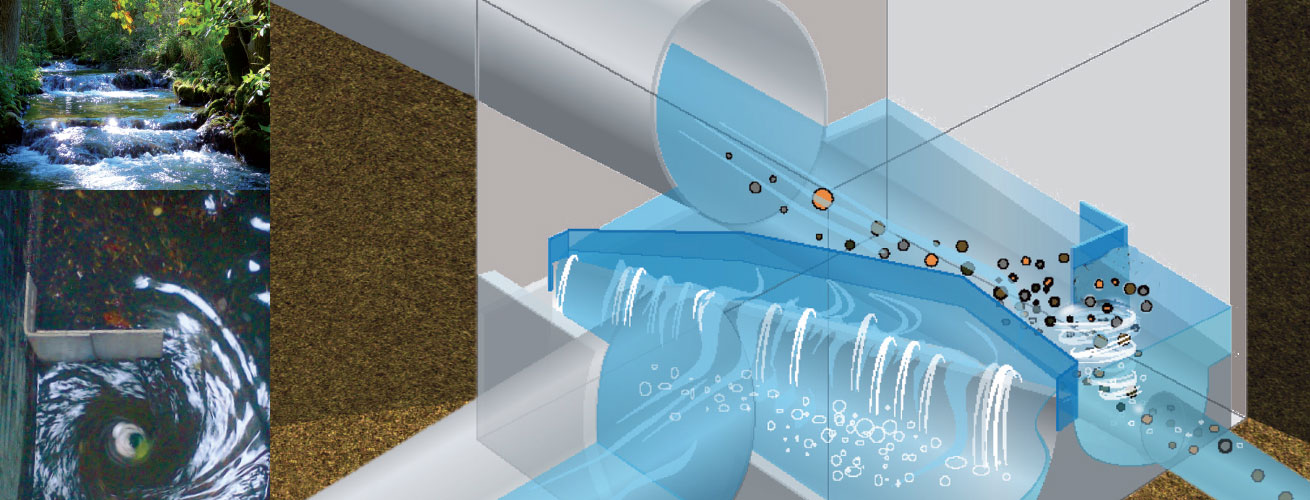

Overflow events within a sewer system can pollute receiving waters with floatables and suspended solids such as plastics, paper and sanitary articles. Fixed scum boards are standard equipment for sewer network overflows and are used to retain floatables as recommended by the German Association for Water, Waste Water and Waste’s guidelines ATV A‑111.

Often the floatables are sucked underneath the scum board to the overflow. This happens when water levels rise after heavy rain, causing strong turbulence, or at dropping water levels because of the large amount of collected floatables in the overflow chamber. The banks of the receiving watercourseare often polluted with clearly visible dirt and sanitarydebris.

The Solution

Bar and brush screens are very effective solutions for retaining floatables and suspended solids within the sewer and allowing the debris to be transported to the wastewater treatment plant. However, stressed budgetary situations often delay such investments. Screening machinery is highly effective but also expensive because the size must match the maximum possible hydraulic spill load.

The HydroSpin® Floatables Removal sets the benchmark with a new working principle. For the duration of the rain event – and even with partial backwater – all floatables are continuously drawn into the continuation sewer and thence to treatmentby means of an artificial vortex.

The System

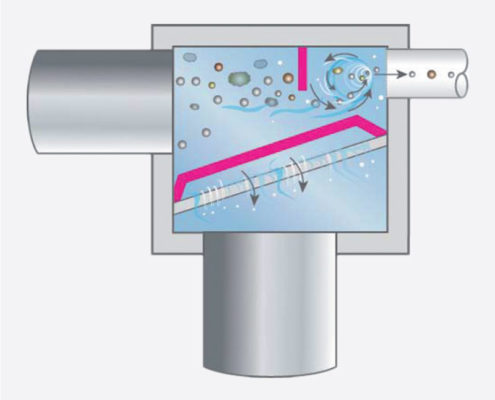

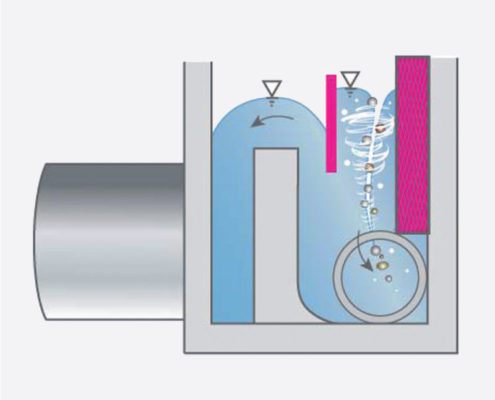

The HydroSpin® Floatables Removal consists of the following chamber components — inflow, outflow and overflow. The system components are a combined guide and scum board, an adjustable vortex plate and a flow-optimized vortex area which can be fitted with additional equipment as necessary. The rotational energy for the artificial vortex is supplied by the flow of the combined sewage within the chamber. In order to generate a visible vortex, the vortex plate must be positioned to create a “flow-optimized vortex area”.

Installing the vortex plate generates a water level difference between the inflow and the vortex area so that the floatables are continuously guided along the guide scumboard to the vortex area and are drawn downwards into the continuation outlet pipe and on to treatment. The guide/scumboard combination has a double function: it is a scumboard preventing debris passing over the spill weirand also a flow-optimised guiding plate for the floatables.

The HydroSpin® Floatables Removal relies purely on hydraulic effects. It works continuously even at partial impound. It prevents an accumulation of floatables so that even with turbulent flow, a reduction of pollutant loading into the receiving watercourse is achieved. The HydroSpin® Floatables Removal is virtually maintenance free; the continuous vortex provides a self-cleaning effect. The continual removal of floating debris into the continuation sewerassists in the prevention of sedimentation and blockages. It is proven that the simple retrofit of existing chambers with the HydroSpin® Floatables Removal increases quality performance and enables a better protection of the adjacent surface waters.

Data analysis from Japan shows an average of up to 78% of floatables and suspended solids can be removed from the overflow using HydroSpin® Floatables Removal (Nakamura et al., 2010).

Efficient performance relies on expert knowledge of the hydrodynamic interrelations between the guide board, the vortex plate and the vortex area. For this reason, the hydrodynamic design should be carried out by Steinhardt engineers. 1,000 installations are already in successful operation.

The Advantages:

- continuous floatable removal

- operates even with partial impound

- counteracts debris accumulation

- no electrical power necessary, water-powered vortex

- optimal environmental protection at minimal cost

- retrofit possible

- no moving parts

- virtually maintenance free