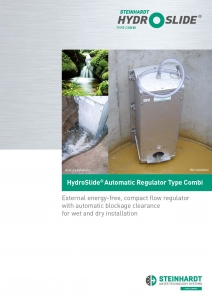

External energy-free, compact flow regulator

with automatic blockage clearanc

for wet and semi-dry installation

The Challenge

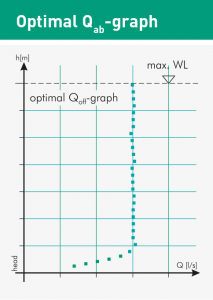

Modern mechanical flow regulators are being specified in increasing numbers to control excessive flows within the sewerage systems. The ideal is where the flow curve is perpendicular providing a constant discharge which optimises the permitted downstream flow rate and minimises upstream retention. These regulating devices are required to provide precise discharge control throughout the regulating range to minimise the cost of storage provision. Steinhardt flow regulators operate safely under these very difficult conditions and provide precise discharge control through-out the regulating range.

The Solution

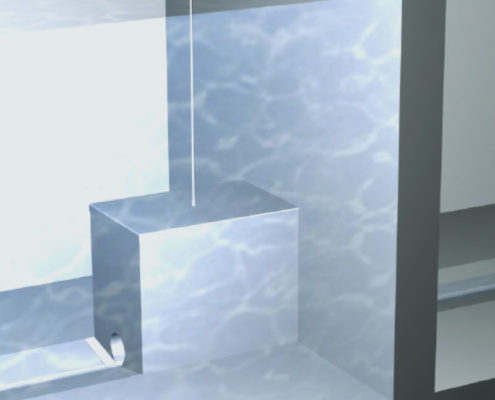

The automatic HydroSlide® Type Combi Flow Regulator is available as Standard (CS) model or as the FlatFlow (CN). Both models combine many functions in one unit: they can be installed on the chamber inlet (semi-dry) or chamber outlet (wet), from raw sewage to stormwater and, where there is restricted space, within the chamber. The regulator housing protects the control mechanism so that no damage is suffered if the unit is submerged. An inspection opening, even if seldom necessary, allows for easy maintenance. On smaller models there are two hoses which are taken to the access cover. One hose is a breather to permit the internal float to rise and fall; the other is a flushing hose which permits the internal mechanism to be cleaned if required. Smaller units are also fitted with a manual pull cable to open the orifice fully if required. These units have an automatic blockage release function and are suitable for use within foul sewerage systems.

The Advantages

- semi-dry or wet installation

- constant discharge (+5%)

- the outstanding feature of the HydroSlide Type Combi is the automatic blockage recognition and clearance

- both models suitable for low impounding heights

- easy to clean, low maintenance

- no external power source required

- operable from above ground

- no sole jump required

- can be completely closed off (optional)

- semi-dry version with vortex-inhibiting inlet pipe

- small and compact

- stainless steel, so robust and durable

- connection for hose flush cleaning from above ground

- pull cable for manual opening up to DR 250

Cost effectiveness

- low-cost

- can be optimised for local requirements

- practically maintenance-free