Automatic flushing siphon for foul and surface water sewers

The Challenge

If the velocity within the sewer is too low, sediments can build up reducing hydraulic capacity and exacerbating smell issues. Conventional cleaning is usually carried out by jetting or tanker flushing. In addition to the high costs of maintaining the sewer by these methods, damage can be caused to the sewer by repeated jetting. As sediment build-up can occur within a few weeks together with the associated odour problem; cleaning has to be regularly repeated.

The Way

Ideally sewers should be cleaned continuously so that sediments do not build up in the first place.

HydroFlush® Sewer Flush Type SH can provide that cleaning by sending a flushing wave periodically to maintain the sewer without operator intervention, utilising collected surface water from adjacent impermeable area or controlled water feed.

The Solution

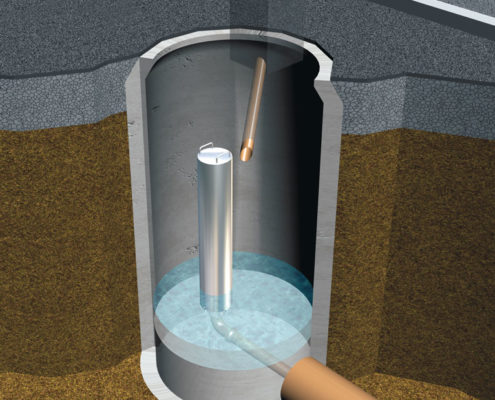

A flushing chamber is constructed containing the HydroFlush® Sewer Flush Type SH unit mounted on an internal base-plate with its discharge pipe directed into the sewer. The chamber fills with water until the top of the siphon is reached; at this point the siphon draws the water from the chamber and discharges it into the sewer in a similar manner to a toilet flush. Steinhardt can deliver a profiling aid for the flushing shaft floor and help to design the flushing chamber. The size of chamber is determined by the volume of water required to flush the problematic length of sewer. The longer and flatter the sewer gradient is, the more flushing water is required. The volume of the flushing water is limited by the shaft diameter and height of the siphon unit. It is important to create a constant and sustained flushing wave with sufficient water to transport the debris to a point where the sewer gradient is then self-cleansing.

The Function

Clean surface water is permitted to fill the flushing chamber. This water can be derived from connecting a small impermeable area adjacent to the chamber via a gully or by controlled clean water supply. When the water level reaches the top of the HydroFlush® Sewer Flush device, water flows over and initiates the siphon effect which empties the flushing chamber of the stored water. Finally the HydroFlush® Sewer Flush draws air as the chamber empties; the residual water in the siphon column runs back into the flushing shaft forming an odour seal. Complex filling routines can be accommodated by valve control utilising timers to permit flushing at desired times of the day / night. The flushing chamber can easily be cleaned if required by removing the HydroFlush® Sewer Flush, the chambers are flushed out and the flush unit reinstalled. It operates automatically without external power. If you wish to flush a sewer with wastewater, please enquire for our special products.

The Advantages

- no electricity required

- no noise

- robust stainless steel

- collects stormwater and domestic/industrial water

- prevents odour formation

- continuous sewer flushing

- constant sustained flushing wave

- odour seal

- low maintenance, can be hosed out

- profiling aid optional

- engineering support from manufacturer