Intelligent discharge control system

high precision — from 5–5000 l/s –

modular extension

The Challenge

Modern sewer networks require intelligent and flexible regulation controls. Measured data must be readily available and values such as Qab configurable by remote control. Ideally, the control system must be inexpensive and suitable for easy retrofit. Only robust and precise systems are suitable for modern wastewater conditions.

The Way

Provision of precise flows and allowing the ability to vary flow (Qab) settings, together with remote control facility with high operational safety, etc. call for intelligent PLC-programmed systems like that of the ElectroSlide Flow Regulator, with upstream control and requiring minimum space for retrofit within existing chambers.

The Solution

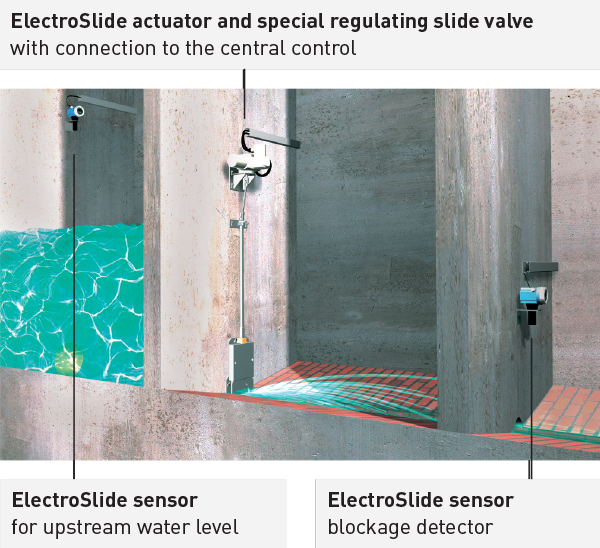

The ElectroSlide Flow Regulator is a specially designed penstock enabling accurate flow calibration. The penstock is driven by an actuator, and can be installed in either upstream or downstream configurations. With high precision, the valve control – see illustration on the left – calculates from the impounded water level, the desired flow rate required (Qab); driving the slide position to provide the aperture area required. Dependent upon the type of control provided, it is possible that flow parameters can be adjusted remotely; however, in most cases the flow changes can be made directly into the plc unit on site. In most applications, a second sensor can be provided downstream of the ElectroSlide Flow Regulator which measures the water level in the discharge channel to ensure flow is being maintained. When the downstream flow is restricted the control recognises that a blockage has occurred and will pulse the ElectroSlide penstock unit open in steps until the blockage is cleared before returning to control. The ElectroSlide Flow Regulator opens the valve gradually to prevent excessive flow passing downstream. Obstructions larger than the valve opening can trigger alarm (optional as GSM signal). Sewer flushing can also be provided within the programme control if required. A specific impounding level can be input and when reached with pulse the ElectroSlide Flow Regulator will open fully for a set period before returning to flow control.

A CP communications processor with ethernet interface is optional for connection to the control centre.

The Advantages

- constant flow regulation

- open, freely programmable PLC control

- blockage recognition and clearance

- no sole jump

- exact flow control, even with backwater

- infinitely variable setpoint adjustment, also in situ

- remote control terminals included

- upstream or downstream installation

- measuring system has no media contact

- robust stainless-steel design

- optional crest measurement

- optional discharge measurement

- optional data logger

- optional GSM detector

Cost-effectiveness

- cost and space-saving as no measurement construction or settling area is necessary

- retrofittable in shafts and basins

- flushes channels

- integrated flood protection