External energy-free separation of coarse, suspended and floating solids in one compact structure

The Challenge

Plastics, glass, packaging and sanitary items pollute our water courses. These items are discharged from sources such as Combined Sewer Overflows (CSOs). Litter accumulates on the highway and adjacent ditches and is then washed into the watercourses during rainfall events. We have to protect our environment to maintain a good quality of life for all — our drinking water must remain affordable and fish remain edible for future generations, too.

The Way

Sedimentation tanks, grit traps, separators, flow bifur-cation systems, baffle plates and screens are commonly used technologies for separating coarse debris, floatables and pollution. According to the A 112 guidelines compiled by the German Society for Water Management, Waste Water and Waste (ATV-DWA) dynamic separation can be used for combined and rainwater system treatment. The Steinhardt HydroTwister® Vortex Separator combines the advantage of all well-known techniques.

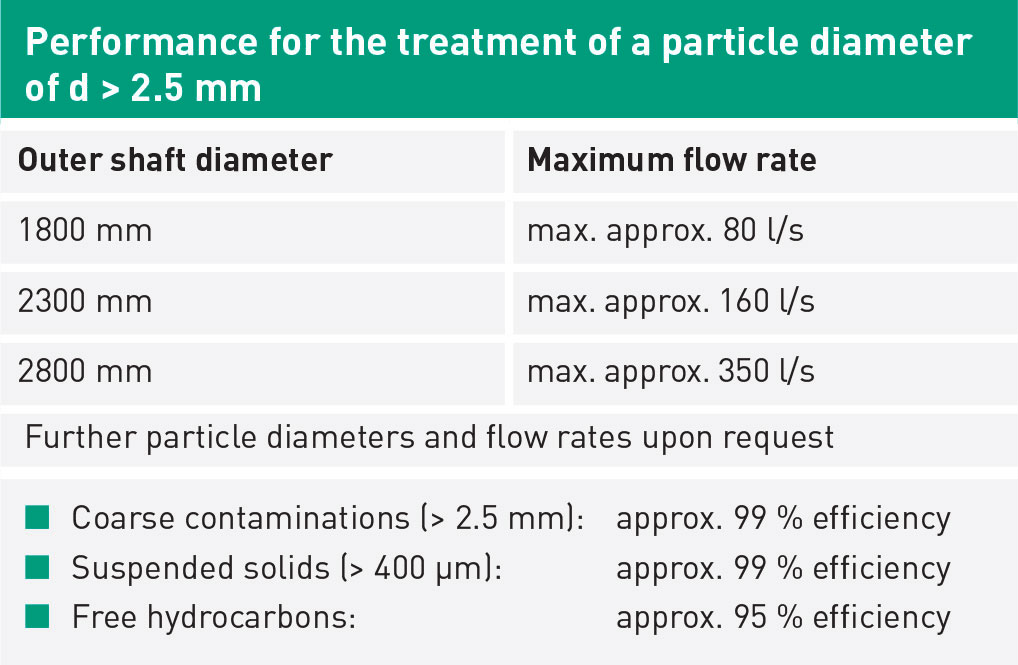

The HydroTwister® Vortex Separator combines 4 treatment methods into one compact system, utilising vortex energy for non-powered operation and self-cleaning of the screen face.

Four functions in one structure:

- debris and grit trap

- screen

- baffle plate

- dynamic separation

The Solution

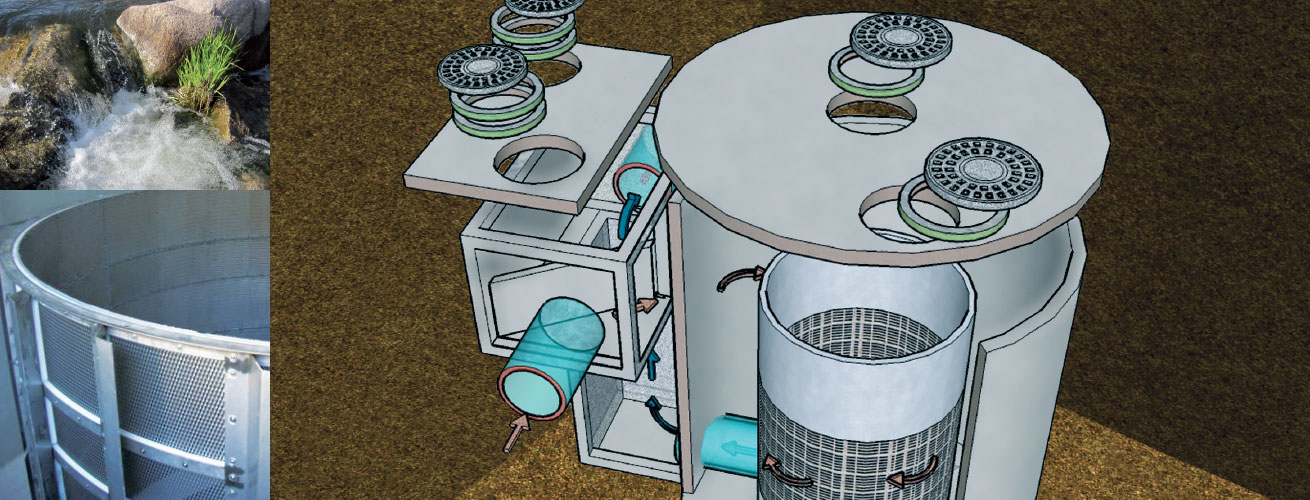

The HydroTwister® Vortex Separator consists of a compact circular concrete shaft with an interior treatment unit, giving a round outer and inner treatment chamber. The interior components are stainless steel and comprise a round baffle plate in the upper zone, a round sieve screen with grater-like slots in the central area and a drain outlet in the bottom which directs the treated water to the discharge pipe or watercourse.

Rainwater or combined sewage flow pass tangentially through the outer treatment chamber. A vortex flow forms and the centrifugal force drives coarse particulates outwards to the concrete wall. These are then transported downwards towards the contamination trap area. Suspended solids of greater size than the screen apertures will be reliably retained. The vortex flow carries the polluting articles continuously around. Heavier particles sink and the lighter particles are retained within the floating solids chamber. The cleaned water that flows through the sieve screen enters the inner treatment chamber and exits the unit via the outlet drain – see cover diagram.

The patented HydroTwister® Vortex Separator is designed as a hydro-dynamic separator. In addition, different screen surfaces and aperture diameters are available to match flow and treatment targets. This unit can be installed in either in-line or off-line configurations. Advanced automation, monitoring and automated debris removal are available options. The Steinhardt team team would be pleased to assist and advise.

The Advantages

- hydro-dynamic solid/liquid separation

- gravity separation

- energy-free, powered by vortex flow

- self-cleaning effect due to vortex flow

- integrated baffle plate

- integrated coarse material trap area

- integrated sieve screen

- high performance

- variable design adapted to the environment

- high reliability

- simple and quick installation

- planning support