Regulating technology, tried and tested

for guaranteed constant discharges

No electrical power required

The Challenge

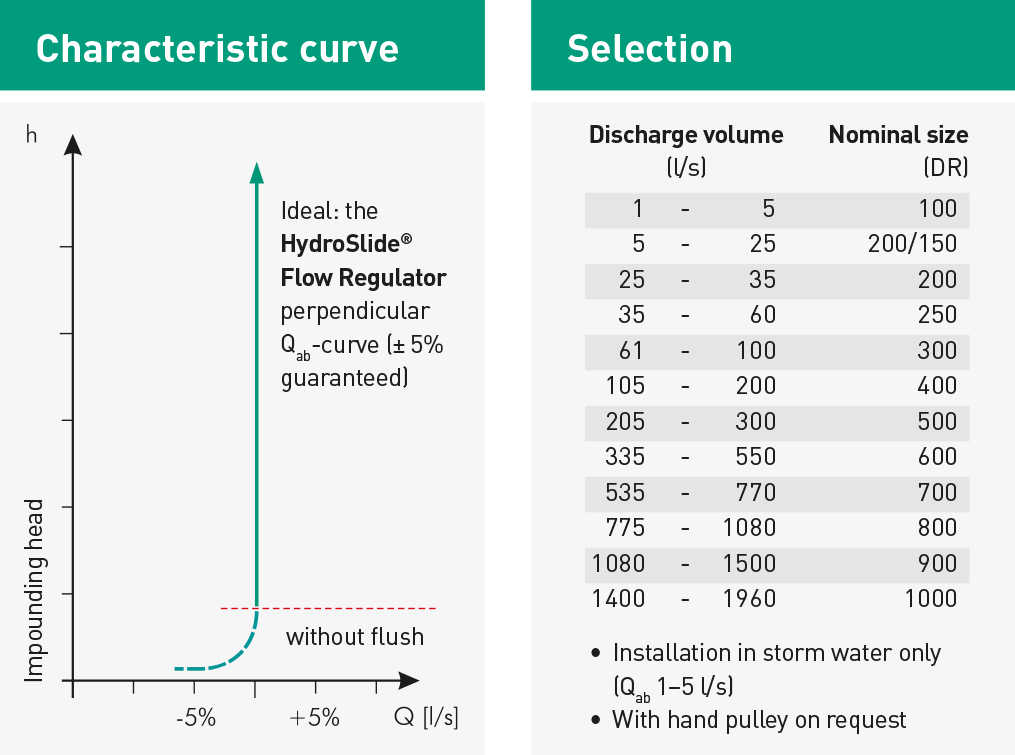

Modern hydraulic management concepts require throttling devices to be considered. The ideal is where the flow curve is perpendicular providing a constant discharge. Throttling controls are required for foul and surface water systems, for watercourses and river control. These regulating devices are required to provide precise discharge control throughout the regulating range.

The Solution

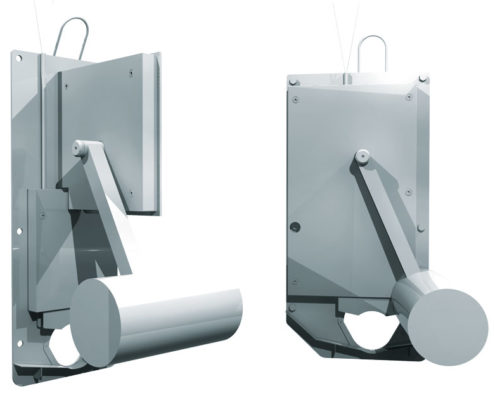

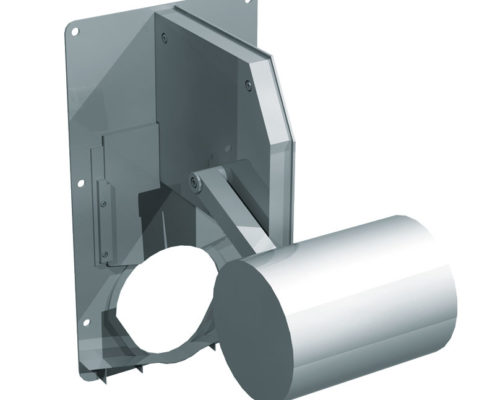

The orifice cross section is adjusted to maintain a constant discharge by a vertically operating shutter plate. The shutter plate is connected to a float arm which relates the water level to a control cam. The precision of the control cam design enables the flow to be regulated to an accuracy of ± 5% from design point. All HydroSlide® Flow Regulators are commonly supplied without a ‘First Flush’ function (see technical documentation); however, a first flush function can be provided for use in foul sewers permitting the initial debris to pass downstream prior to regulating. In such cases, the HydroSlide® Flow Regulator can be adapted to any required setting. The regulators of the model series DR 200 or smaller have a double valve. A pull cable is standard for discharges less than 60 l/s to enable manual opening of the unit in case of blockages, although in foul sewers automatic opening operation is recommendable for discharges ‹ 25l/s. When manually opened, the HydroSlide® Flow Regulator opens the whole orifice to enable debris to pass through. All regulators are provided with a benching profiling guide.

The HydroSlide® Flow Regulator models VN and VS are fitted with a shutter plate controlled by a float arm, which moves the plate vertically within the outlet orifice. The entire control mechanism is fully protected from collecting dirt by a housing cover. Two hand pulleys enable the safe manual opening of the regulator unit’s outlet from ground level in the case of blockage or if upstream flushing is required.

The Advantages

- no external power source, no electricity

- simple, robust construction

- rope pulley — manual opening from above ground (up to and incl. DR 250)

- control mechanism protected by housing

- no sole jump

- without initial flush

- wet installation avoids separate shaft

- favourable discharge cross-section during throttling

- adaptable for other discharge parameters by exchanging disc cam

- optional: VARIO function for Qab setting