High-performance modular screens for Combined Sewer Overflows (CSO)

The Challenge

Even when Combined Sewer Overflows (CSO’s) and Storm Sewer Overflows (SSO’s) are equipped with scum boards or lamella baffles, considerable quantities of floatables and suspended solids still reach the receiving watercourse. Sanitary articles, toilet paper and synthetics are left caught on the river bank after heavy rain; these waters become biologically and hydraulically “stressed”.

The Way

All polluted discharges into receiving waters have to be treated. Floatables and suspended solids can be screened out. This should be done continuously and carefully to prevent the screenings from breaking up and slipping through the screen structure.

The Solution

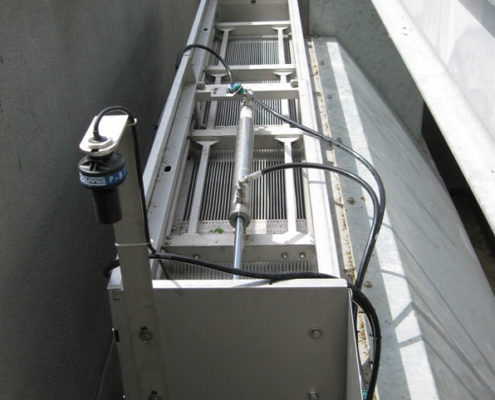

The Steinhardt® HydroScreen Fine Bar Screen Type FSRF is a flat bar screen. It is installed horizontally on the overflow wall within combined sewerage systems. The spill flow rises up through the bars retaining the debris within the foul flow. All fine bar screens Model FSRF are made of stainless steel and are typically hydraulically driven, there-fore not requiring explosion protection. The control cabinet can be in any chosen position above ground.

The HydroScreen Fine Bar Screen Type FSRF is modular in design and can be installed through small openings (min. Ø 600) and assembled in the structure. The drive module is 1.30 m long and incorporates a hydraulic ram. Up to 4 slave units can be connected to the drive unit to increase the screening rate to suit the application. To prevent screenings being carried over the whole length of the screen, each module has rest zones. The screenings are released there assisted by the under flow and are carried away by the sewer flow.

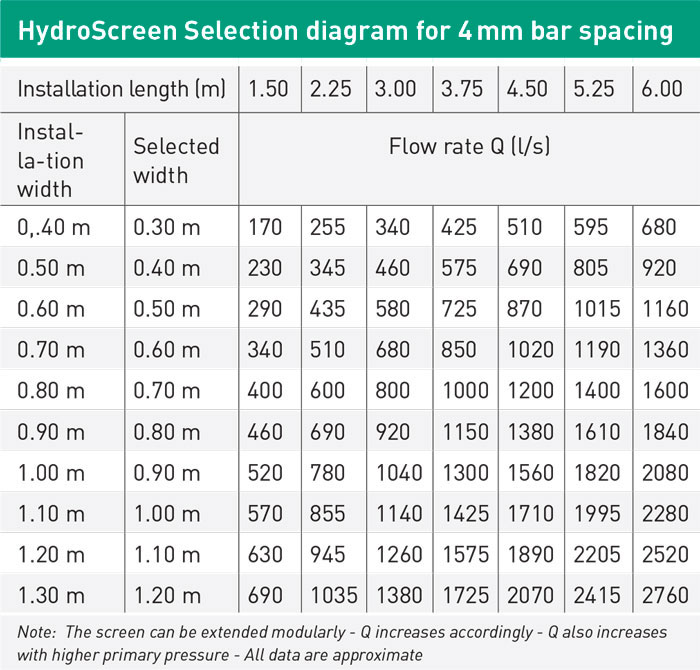

The minimum screen width starts at 40 cm and can be extended in 10 cm wide steps up to 1.30 m width. The screen height, including the hydraulic drive, is less than 40 cm when assembled. It is installed horizontally, permitting the whole screen to be utilized to screen the flow at all times, thus minimising the velocity through the bars.

The standard bar spacing is 4 and 6 mm which ensures the highest possible degree of cleaning by corresponding flow rate. In order to trap as much dissolved matter as possible, the flow velocity between the screen bars is limited to ≤ 1.4 m/s.

The spacing between the bars is automatically raked when the spill commences and continues until the spill event finishes maintaining the screening capacity.

HydroScreen Fine Bar Screen Type FSRF is designed for a max. impounding head of 2x overflow height. If higher overflow heights are expected, e.g. in emergency situations, the screen should be reinforced.

Range of Application

- before combined inflows into receiving waters

- before storm water inflows into receiving waters

- before soil filter systems

- before earth and retention basins

- before percolations

- before difficult-to-clean basins

The Advantages

- robust stainless steel construction

- modular in construction

- retrofit through small apertures possible

- high cleaning efficiency

- head loss approx. ≤10 cm

- velocity between screen bars limited to ≤ 1.4 m/s

- effective performance approx. 500 l x s-1 x m-2

- bio oil

- screenings release zone every 65 cm

- stainless steel construction

- no re-adjustment