Effective stormwater treatment

with moving lamellae –

no external energy required

The Challenge

Rainwater carrying impurities from paved and sealed surfaces in built-up areas and drainage from roads lead to serious pollution of receiving waters. Aside from accidents involving hazardous materials, this “normal” contamination is made up largely of substances in the form of suspended solid particles which are the major cause of ongoing water pollution.

The Way

At around 70%, suspended solids (< 200µm) make up the largest part of floating substances. Most suspended solids respond to settlement. A simple sedimentation treatment can contribute significantly to an effective reduction or complete avoidance of impurities at the outflow. Modern wastewater treatment focusses on stormwater settling tanks as the central treatment organ.

The installation of technological components – lamellae – can improve the settlement performance of stormwater sedimentation basins considerably, reducing construction size and also saving investment costs.

The Solution

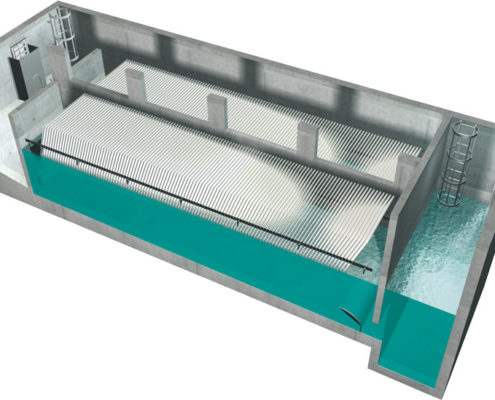

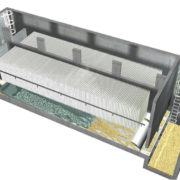

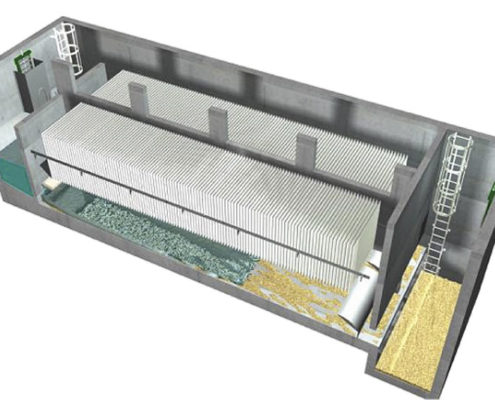

The HydroM.E.S.I. Particle Separator is specially designed to deal with particle-based water pollution. Whilst in operation the lamellae plates are submerged; the pollutant impurities are bonded to the fine suspended solids. These solids are settled to the floor of the tank as the untreated water flows between diagonally-inclined lamellae plates. Free-floating light substances, such as oil or hydrocarbon compounds, are treated by coalescence.

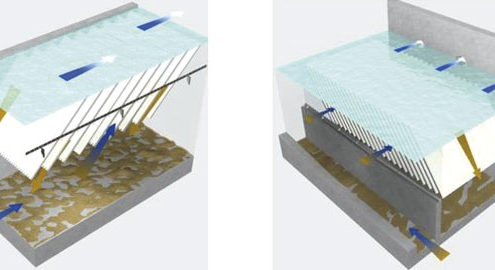

The HydroM.E.S.I. Particle Separator is equipped with a flexible lamella structure whose angle of incline is adjustable. On filling, the rising water level moves the lamellae from the vertical position into the pre-programmed operational angle, float-controlled and with no external energy source. The distance between the individual lamellae is variable and, if required, can be adjusted to increase purifying efficiency after installation.

The water to be treated flows through the sand and grit trap into the separation chamber where it rises through the diagonally-slanting lamellae from bottom to top, separating the suspended particles. Settled substances accumulate in the form of sludge on the tank floor. Floating and light materials collect on the surface and are kept from flowing out of the system by a scum board. The treated water flows out of the particle separator through an open channel. (Annual average retention of fine filterable substances up to approx. 70% and up to 53% of these substances < 63 µ)

After the HydroM.E.S.I. Particle Separator is emptied, the lamellae return automatically to their vertical position. Any particulates remaining on the surface of the lamellae fall down to the basin floor. A flush wave washes the settled impurities on the basin floor into the sand and grit trap for disposal (suction device, pumps, etc.).

On request the HydroM.E.S.I. Particle Separator can be supplied with an integrated cleaning system, an auto-mated sludge disposal unit and a filtration unit. (Annual average retention of fine filterable substances up to approx. 90% and up to approx. 80% of these substances < 63 µ).

The Advantages:

- compact construction

- only slight head loss

- free of external energy

- modular extension

- large retention or settling surfaces in a small area

- variable design or upgrading to optimal ecological or economic limits