Innovative inverted siphon flush for continuous cleaning of underpass pipes

The Challenge

Sewer networks are generally operated by gravity and are laid to the local topographical conditions. Deep sewers are expensive, pumping stations are expensive and not always desirable, so when obstructions such as watercourses, roads or railways are encountered solutions such as inverted siphons are often employed. All inverted siphons require regular maintenance as they are prone to sedimentation due to low velocities.

Up to now, inverted siphons have been cleaned with clearing blades, flushing and force pumps from an up-stream position. Flushing from the siphon head is of limited success as the flush takes place in the water cushion of the inverted siphon where the force is dispelled.

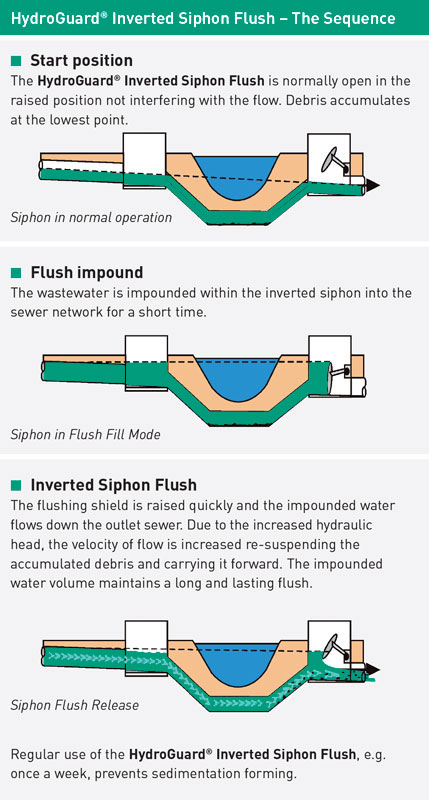

The Way (patented)

Water is non-compressible and for this reason, it is better to install flushing devices downstream which draws the water instead of compressing. When the HydroGuard® shield is lowered into the sewer, this stops the flow from continuing downstream and at the same time, impounds the flow within the inverted siphon and the upstream sewer network. This impounding stores the required flushing volume and raises the hydraulic head across the siphon section. When the HydroGuard® shield opens, the stored water creates a powerful, almost turbulent, high velocity flush. The water level quickly drops upstream and air is drawn into the inverted siphon. The water becomes compressible and its increased mobility provides the pressure shocks (water hammer) required for the improved cleaning result (see illustration).

The Product (patented)

The HydroGuard® Inverted Siphon Flush is installed downstream of the inverted siphon at a convenient manhole. It consists of a flushing shield, an electro-hydraulic drive, water level sensors upstream and downstream as well as on-site controls with optional remote controls.

Areas of Application

- underpassing waters

- underpassing traffic routes

- underpassing buildings

The Advantages

- robust stainless-steel construction

- retrofit, also through small openings

- space-saving

- hydraulic drive

- automatic operation

- continuous flushing

- high operational safety

- large hydraulic flow

- high flow velocity

- high shear stress

- high degree of cleaning

- no readjustment

- design support from Steinhardt