Self-cleaning brush screen for CSO discharges – external energy free, hydraulically or electric-powered

The Challenge

Many watercourses are blighted with sanitary debris dis-charged from sewer overflow systems. Steinhardt offers a range of HydroClean® units that can be used to screen storm overflow discharges preventing unsightly pollution debris. The standard units are water powered and require no control panels or electrical input; ideal for rural areas where a mechanical screen is desirable but the cost of providing the power is high.

The EU Water Framework Directive and the national water management legislation of the individual EU states provide the basis for the best possible protection of our waters. One requirement is that all inflows and discharges are to be equipped to optimal, technical standards.

The Way

Screens are a highly efficient solution: there are perforated screens (up to 20% SRV*), bar screens (approx. 20 – 40% SRV*) and brush screens (approx. 40 – 60% SRV*).

The Solution

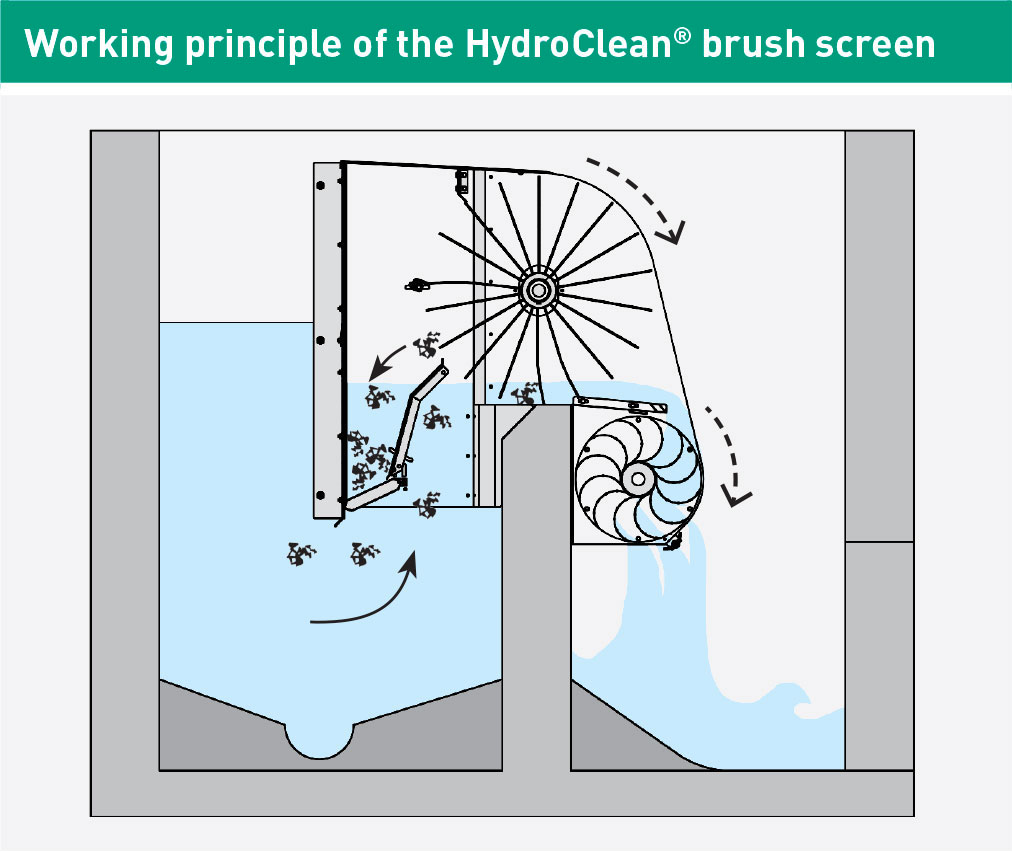

The HydroClean® self-cleaning brush screen traps solid pollutants reliably and continuously within a collection chamber. After the overflow event, the debris is returned to the sewer to be treated at the WWTP. The HydroClean® brush screen uses waterwheel technology and operates without electrical power. It is easy to retrofit, even through small manhole accesses, since installation is carried out with modular units.

The high cleaning performance of the HydroClean® brush screen relies on the brush itself as the pollutant trap; no perforated plates or bars are necessary. Conventional screens, on the other hand, use brushes to clean the trapping bars or perforated plates, thus fragmenting the screenings and lowering the efficiency of the installation.

Power Units

As an alternative to the non-powered, energy-free waterwheel drive,

Steinhardt can provide electrical or hydraulic powered units. These are normally selected where levels do not permit a water wheel to be utilised.

Customised solutions include fully removable screen units for use in hazardous atmospheres where man entry is not desirable. (slide in/slide out).

* Results of a Japanese study

SRV = Screening Retention Value

The Advantages

- brush bristles act as pollutant trap

- continuous self-cleaning

- bristles guarantee operational reliability – no jamming

- optimal cleaning performance owing to counter-rotating brushes

- robust construction

- durable wastewater-proof materials

- awarded the Ernst Kuntze Prize

Cost Effectiveness

- investment costs reduced

- savings on operational costs with continuous self-cleaning and external energy-free waterwheel technology

- low maintenance

- low equipment costs

- retrofit, even through small manholes

- modular design allows greater adaptability