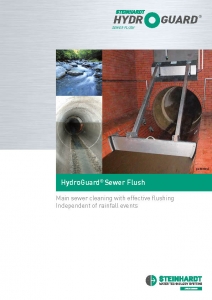

Main sewer cleaning with effective flushing

Independent of rainfall events

The Problem

Deposition of grit and assorted debris is a frequent problem in all types of sewerage systems. The most common causes are large pipe diameters with small dry weather flow rates (aggravated by water-saving initiatives), poor gradients or sagging of pipes due to geological influences, etc.

Deposition can result in higher pollutant loading at stormwater overflows, intermittent biological loads to sewage treatment plants, odour problems, a reduction of hydraulic capacity of the pipes or damage to the pipes by sulphur corrosion.

The Solution

The HydroGuard® Sewer Flush is a device for continuous, automatic cleaning of medium-sized pipes (DN 600 — 3000).

Use of the HydroGuard® Sewer Flush reduces the frequency of overflow spills, equalizes the biological load passing down to the treatment plant, extends the lifespan of sewer pipes, prevents odour formation and avoids maintenance costs associated with regular tanker flushing.

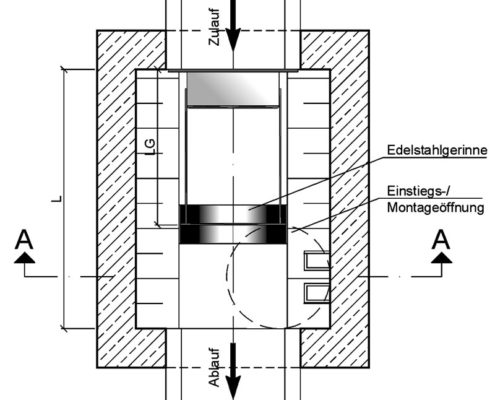

Continuous flushing using the dry weather flow prevents the build-up of silts and debris. Pipe sections downstream of the flushing device are cleaned by the powerful flushing wave. The upstream section, used to impound the flushing water, is cleaned using the energy produced by the sudden falling water-level (draw flush).

The HydroGuard® Sewer Flush can be programmed for a powerful flushing wave for thorough cleaning and smaller waves as preventative measures at selected times.

Additionally, the device enables versatile and flexible sewer management. The water is impounded and retained in the upstream pipes for a time, to be released later at a pre-determined water level when the flush water volume has been reached. The design takes into account the volume needed to effectively clean the required length of sewer at the existing gradient.

According to the German ATV A 128, static pipe volume can be used to enhance required storage basin volumes. With the HydroGuard® Sewer Flush additional volume from the retention pipework can be activated, reducing the requirement of separate storage constructions. In a “best-case” scenario, the construction of new overflow chambers or attenuation tanks can be avoided completely. When dimensioning storage tanks, the A ATV 128 also permits the additional “over design volume” (to allow for siltation) to be reduced, or even dropped completely, if silting is avoided by flushing with the dry weather flow.

Due to its small footprint and utilisation of the existing pipe as storage volume for the flushing water, the HydroGuard® Sewer Flush can be retrofitted into existing systems.

The Advantages

- prolonged, high-energy flushing wave

- flushing of long sections of pipework with single flushing shields

- flushing of long dis-tances, e.g. 6 km, using a series of networked HydroGuard® Sewer Flush units

- effective downsurge flush up to 2/3 of the impound range

- high flushing frequency – excellent cleaning results

- variable flushing volumes

- flushing frequency freely selectable

- local and/or remote-controlled system

- operation independent of weather conditions

- retrofit possible, easy integration into existing pipe systems

- no sole jump

- shield moves upwards completely clear of the pipe cross-section

- shield over- and underflow possible

- no separate storage chamber necessary for the flushing water

- all parts accessible even during sewer operation

- suitable for pipe sewer management

- for pipes from DN 600 up to 3000