Electrotechnology

Electrical planning for modern sewer and stormwater management

Execution planning with functional guarantee

The electrician’s language is the circuit diagram. We offer you detailed design in accordance with the operational conditions of stormwater treatment. We structure your hardware set-up (operational equipment) and develop the necessary software according to your requirements and needs. You will have access to the wide experience of a team of civil and construction engineers, electrical and chemical engineers. We provide single-source service with functional guarantee.

The detailed planning has to take into consideration the filling level as well as the force necessary to move the flushing shield in the sewer; the image shows a completely functional model of our HydroGuard Flushing and Impounding Protection.

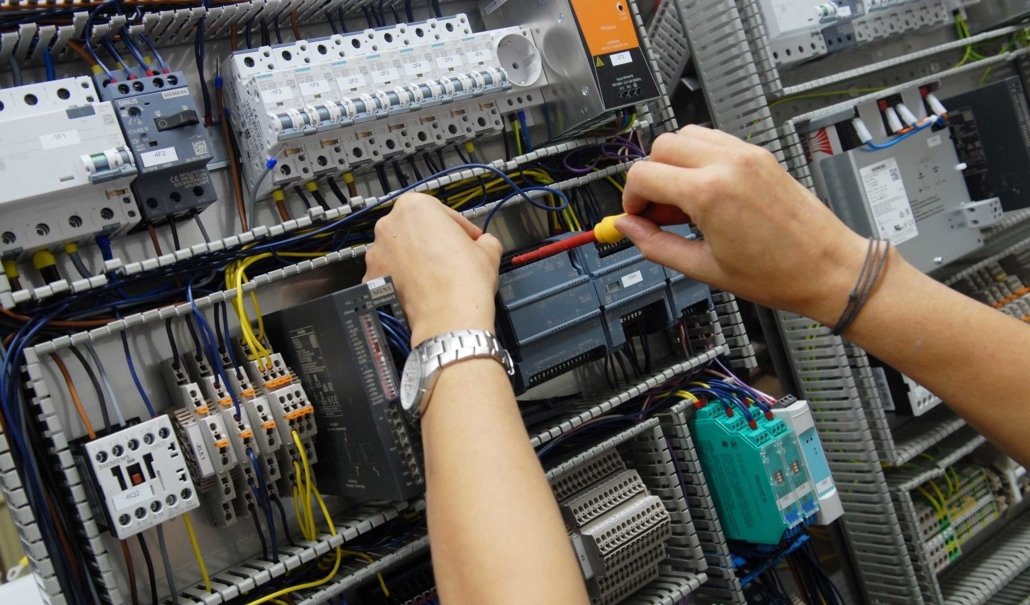

Electro-hardware, tailored to your requirements

Instrumentation includes all control cabinet components which have been determined during electrical planning and tied together in the detailed planning. All Steinhardt control cabinets are custom-made according to the type of technology, the installation location and intended operational field.

Every control cabinet is individually designed and hand-assembled.

Typical components include:

- Input panel

- Emergency stop

- Electrical supply

- SPS

- Backups

- Light

- Power points

- Transmission unit, etc.

Control cabinet assembly with components

Automatising your stormwater basin or flood protection plant

Depending on the equipment and the measuring technology in question our experienced staff will take over the programming of your entire plant, working to predetermined flow charts. Your individually fixed specifications form the basis for the job.

Your advantages:

- use of a multi-disciplined team

- use of our complete range of know-how

- use of existing mature program modules

- use of our specialist knowledge in the fields of rainwater and wastewater treatment and flood protection

- use of our in-depth know-how in the fields of discharge control, regulation and measurement

- use of our experience in process planning

Model example – Stormwater treatment in the Sipplingen district

In 2006, on the advice of the lower water authority of the Lake Constance district, the combined sewerage system of the local authority in Sipplingen was reassessed by means of a pollution load investigation.

As a result, it was necessary to increase the storage volume of the storm overflow basin “West”/Sulzbach spillway. At the same time, the installation of a lamella particle separator was planned to reduce the surface load of the stormwater tank for a given design discharge and so decrease solid and pollutant load emission into Lake Constance via the spillways. These measures are also intended to ensure compliance with the Lake Constance guidelines in the future.

Steinhardt GmbH Wassertechnik was involved in the implementation of the concept right from the planning phase and has provided all plant components for across-the-board equipment for the refurbished overflow system. In addition to the HydroMESI lamella particle separator, which increases the sedimentation capacity of the basin, a motor-controlled ElectroSlide slide valve for the regulation of the dry weather discharge and an automated HydroScreen fine bar screen for the retention of coarse material were installed in the inlet area. The cleaning concept is supplemented by a HydroSelf tank flushing system, which effectively feeds solids sedimented on the tank bottom after rain events to the pump sump of the treatment plant.

By means of intelligent control logic, the individual plant components are effectively coordinated with each other. The overall concept enables the officially specified discharge quantities to be adhered to and the pollutant loads to be effectively reduced. The new conception of the Sipplingen stormwater overflow basin is an example of modern state-of-the-art rainwater treatment to protect the valuable drinking water reservoir, Lake Constance, from anthropogenic pollution.

Easy-to-understand control panels

Self-explanatory product-related control panels are mounted on the control cabinets enabling simple and intuitive operation control by means of product illustration and function animation.

The animation visualisation sequences can be customised according to client request or taken from our stock of existing templates.

Animated process visualisation for monitoring the drainage of a pump sump and the operation of a gate flushing system.

Approved safety and functionality

Steinhardt GmbH has been manufacturing control cabinets (for indoor or outdoor installation) since 1981.

During the production phase in Taunusstein, equipment and software are combined and subjected to intensive functional testing. Following this, operational safety is confirmed by means of extensive test protocols. Only after approval — and certification if necessary — will the complete unit be shipped. The control unit is assembled on site and then subjected to a repeat test for function and safety.

Control cabinet production

Even control cabinets which have not been assembled in-house are functionally tested, approved and certified. They are put into operation using central power connectors

Connection to a telecontrol system is possible at any time, should the client so wish. Only free software from Steinhardt GmbH is used to ensure access for third parties at all times.

Data logging and analysis

Steinhardt GmbH offers data logging of your equipment with corresponding analysis, for example to identify maintenance requirements.

Steinhardt GmbH also offers the service of compiling a data bank of all Steinhardt plant within your area of responsibility.

Over and above this, we can perform remote maintenance via remote access, thus cancelling call-out charges and travel costs.

So, for instance, in collating overflow data, such key markers as water level, overflow intervals and volumes can be recorded on the spot or transferred via internet. We would be happy to take over the analysis of the collated data for you, to redact it and re-direct it to the relevant authority.

Nowadays digital methods of visual inspection save on personnel and maintenance costs. Send us your enquiry.