Drive Technology

Harnessing water power

The sustainable use of waterpower is one of Steinhardt’s specialities. Stormwater treatment units are often extremely difficult to access and installed in locations where an electricity supply would involve high costs. Additionally, combining electricity and water presents risk potential that must be taken into consideration at the planning stage.

More sustainable and less maintenance-intensive are units that exploit the forces of gravity, buoyancy and water pressure, all of which exist free of charge.

Innovative solutions such as waterwheel drives, float controls, outflow regulation or solids removal using a dynamic vortex are principles which find their application in Steinhardt GmbH’s patented products.

HydroStyx Discharge Brake with external energy-free float control

Tried and tested electro motors for low-maintenance operation

Steinhardt GmbH procures actuators from firms such as Auma or SEW. Our choice and design vary according to the product and the local requirements. Combining these factors allows us to guarantee you a harmonious valve and actuator unit.

The design nonetheless requires information on the nature of the installation and its maximum power supply. Please note that not all electro motors can operate 100% of the time as cooling periods are necessary. Not every electric motor is compatible with every control; some motors have integrated controls.

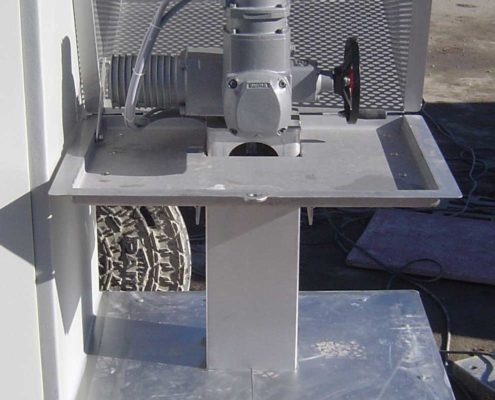

An SEW electric gear motor for driving a HydroClean Brush Screen

Motorised gate valves exist in various designs and differ mostly according to application. For example, there are motorised gate valves which open just once a year and others that open several times an hour. There are also gate valves which are adjusted every second, for example as flow regulation. This involves complex switching operations, the coordination with the valve is necessary to avoid failure. In particular, where intensive switching is required under high water pressure conditions, high-quality gate valves and high-quality actuators must be installed. Under such conditions the Steinhardt products ElectroSlide and Easy Slide have proven successful.

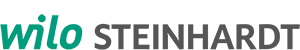

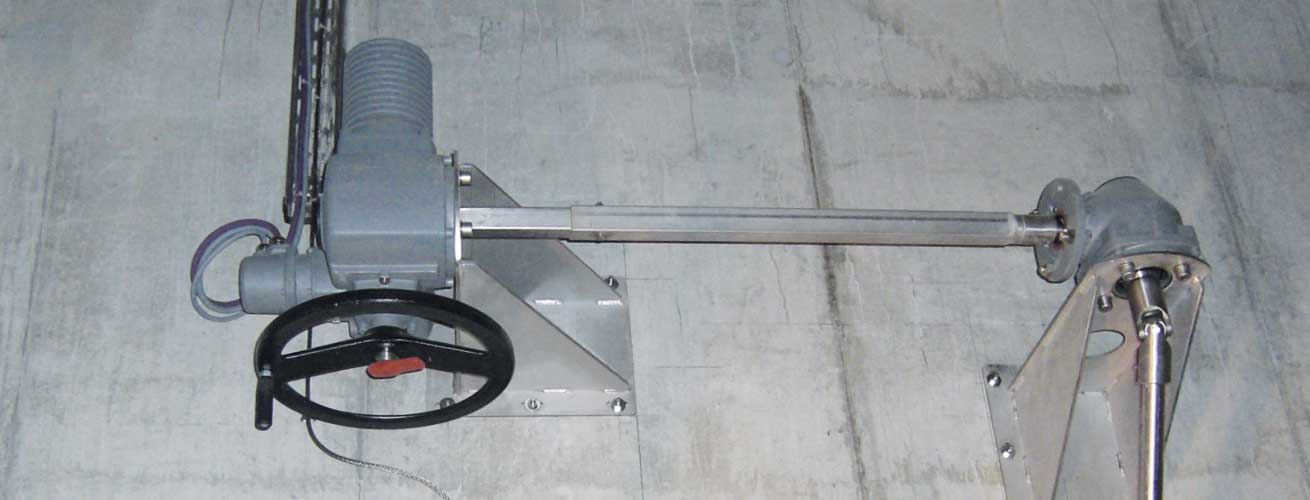

Examples of gate valves with spindle drive for opening and closing:

Auma electric actuator for opening and closing a gate valve

Custom-made hydraulic drive systems

At Steinhardt GmbH we assemble most of our hydraulic systems ourselves, tailored to local requirements. We construct mirrored hydraulic units with emergency features or hydraulic systems with pressure accumulators or hand pumps.

The driver units can be divided into three groups:

- 400 V drive

- 240 V drive

- 24 V for use with solar technology

We can provide assistance for or complete your

- hydraulic planning

and/or

- implementation planning

Let’s talk about how we can help!

Hydraulic actuator with manual operation

Hydraulic control for a HydroSelf Flushing System with 9 gates – extendable up to 24 gates

Pneumatic drives – especially for flood protection

Owing to their tendency to produce condensation, pneumatic drives are seldom used in wastewater or sewerage systems. They require complex controls and are comparatively expensive. Hydraulic drives are generally more favourably priced and also provide greater operational security.

Outside the sewerage system, however, we gladly offer pneumatic drives, for example for contact modules. These are used in flood guarding and, in particular, for property protection.

Pneumatically-driven bulkhead seal protecting courtyard and garage entrances against flooding

Pneumatic controls can be fitted with security features so that the operation of your gates or protective equipment is ensured, even during a power cut. Should you prefer a system independent of electricity, compressed air or a hand pump can be fitted.

Pump technology for all applications

Pumping is an effective method of raising water and, therefore, of either emptying or filling tanks and basins. Depending on the area of application, a drinking water or a sewage pump is fitted. For use in the sewerage systems or for flood prevention sewage pumps are installed as the distance between the impeller and the pump casing is greater. This lessens abrasion in the case of sand entering the works.

In order to deal with cloth remnants and the like, drainage pumps are fitted with cutter wheels. However, modern wet wipes still present these pumps with a particular challenge that necessitates frequent maintenance work. An upstream bar screen can improve such situations.

Here are three examples of the application of different pump types:

1. Filling pump

Filling the HydroSelf Tank Flush

2. Drainage pump

Drainage pumps for the HydroSelf Gate Flushing System

3. Bilge pumps

Bilge pump

Products and services for sectors Drive Technology and Electrotechnology