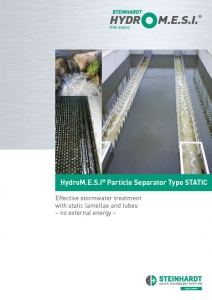

Effective stormwater treatment with static lamellae and tubes – no external energy

The Challenge

Discharges from combined and separate systems are highly charged with solid contamination and contribute to the pollution of receiving waters. The solids themselves act as transporters of a diversity of further pollutants such as heavy metals, PAH, petroleum-derived hydrocarbons or endocrine disrupters. In particular, fine particulates and organic solids with their high absorptive capacity are well-suited to bind pollutants.

Against this background, the retention of fine particulates has become an important goal in modern stormwater treatment. The cumulative parameter “fine filterable substances” (‹ 63 µ) will most certainly replace fine fractions of solids as the indicative parameter for future emission requirements. The elimination of fine particulates is a challenge for stormwater plants and only possible with the deployment of adequate filter systems or optimised sedimentation plants. For operational reasons and owing to its specific space requirements, the sedimentation process has become the norm within the framework of standard treatment. However, a paradigm shift can be observed in stormwater treatment towards locally adapted “stormwater management concepts”. This approach calls for an innovative, practicable and flexible treatment model as exemplified by the HydroM.E.S.I.® Particle Separator.

The Solution

The HydroM.E.S.I.® is a flexible system, extendable by modules, for the high-performance separation of particulates by sedimentation from combined and surface water discharges. The HydroM.E.S.I.® particle separator type STATIC is equally suited for the new conception or retrofitting of central sedimentation plants or for installation in a decentralised treatment system.

The performance of the HydroM.E.S.I.® particle separator type STATIC is measured in relation to specific local requirements. It is installed in a concrete or plastic structure and consists of fixed, diagonally-inclined lamella bundles with a honeycomb structure. The process of solid sedimentation takes place inside the lamella under a favourable upwards flow. The particles settle on the lamella surface and fall downwards to the water and particulate mixture to the bottom of the tank structure. The geometrical design of the separator provides a large settling surface which reduces the treatment system’s load significantly whilst at the same time boosting its performance.

In contrast to conventional designs, the installation of a HydroM.E.S.I.® particle separator in a newly planned stormwater basin will reduce the basin volume and save on investment costs.

(Annual average retention of fine filterable substances up to approx. 70% and up to 53% of these substances ‹ 63 µ)

The standard lamella honeycomb bundles for the HydroM.E.S.I.® particle separator type STATIC are manufactured from polypropylene (PP). Stainless steel is available on demand. An optional filtration can be supplied for specific operations to increase the average annual retention rate to approx. 90% of fine filterable substances (approx. 80% of these substances ‹ 63 µ)1.

The Advantages:

- low investment costs

- for deployment in central and decentralised stormwater plants

- large projected settling surface within a small place

- flexible, modular extendable system – by order in stainless steel

- no external energy required

- flow-optimised components, low loss of height

- system design by Steinhardt engineers with years of

expertise

1 Source: Final report 02/2017, HA Project no. 453/14–13 „On-site measurement programme for a semi-centralised plant for treating highly contaminated road runoff“, Frankfurt University of Applied Sciences, Research Group Urban Water and Hydromechanics, Prof. Dr.-Ing. habil. Antje Welker, Prof. Dr.-Ing. Carsten Dierkes