Delays discharge and activates unused sewer volume

The Challenge

Measures to protect properties from flooding are necessary but often expensive. The common method to attenuate flows is with the construction of storage tanks to absorb the peak flow. Because of the huge investment costs involved, local drainage undertakers are often unable to realise such construction measures. Action is also called for when old sewers in an established urban area are overburdened by connection to new development. The provision of large attenuation structures within older parts of the urban area are frequently not possible due to lack of space.

The Solution

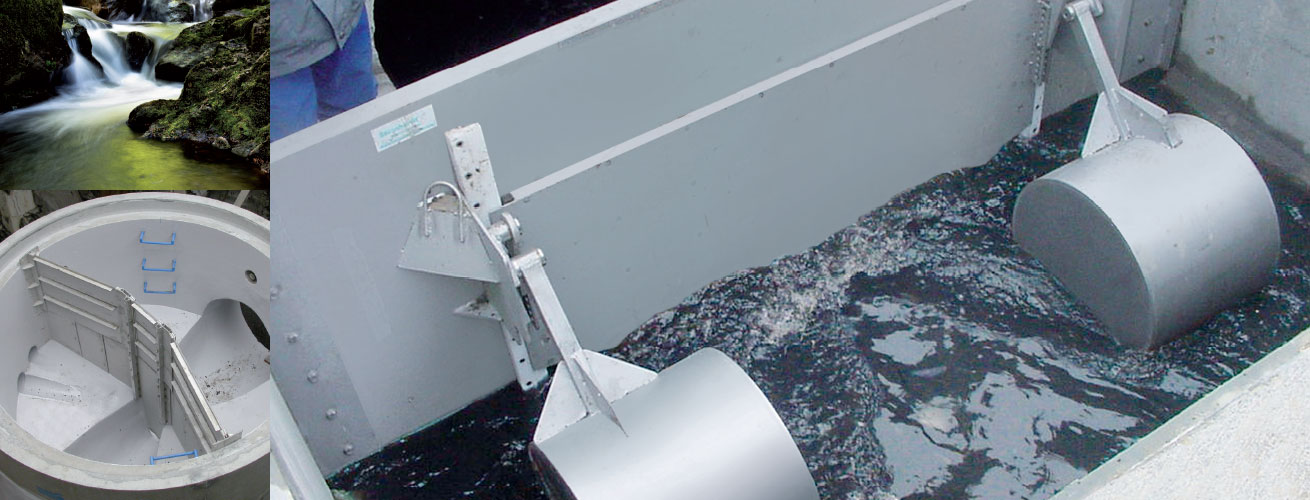

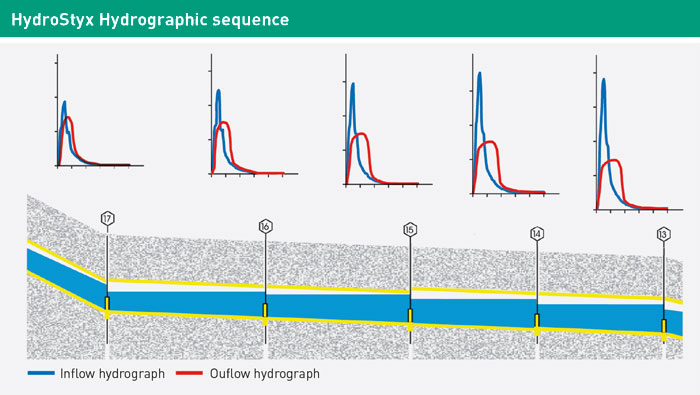

A sewer system usually has large amounts of unused storage capacity since it was designed to cope with peak flows. The HydroStyx® discharge brake allows this hidden capital to be utilized. During heavy rain, the HydroStyx® discharge brake allows the free sewer volume to be used as storage. The flow in the trunk sewer is regulated to enable unused volume to be used as attenuation. Hydro-Styx® discharge brakes are installed within chambers along the length of the sewer to form a cascade. A calculated Pass Forward Flow (PFF) is allowed to flow down the sewer section. When the storm flow rate increases, the brake causes the flow to surcharge upstream. The debris in the water sink and are transported to the treatment plant. As the storage volume is used, the combined water flows over the crest of the brakes and the sewer regains full capacity. The retained water contains fewer pollutants, the discharge hydrograph shows that the storm peaks are attenuated reducing the downstream flood risk. Expensive sewer enlargement or attenuation tank provision may not be necessary as the existing sewer volume can now be mobilised.

The design of the HydroStyx® discharge brake requires qualified engineering calculations of the sewer network. We can recommend useful software and supply you with competent personnel.

Cost-effectiveness

- saves on construction and investment by activating available storage volume in sewer channels

- replacement of sewers no longer necessary

- fewer basins required

- maintenance-free

The Advantages

- discharge peaks are evened out

- discharge flows are decelerated

- overflows are reduced

- treatment plant operation is optimised

- effective use of sewer network volume

- hydraulic and ecological stresses are avoided

- no electricity required – external energy-free

- robust, stainless steel construction

- retrofit in any shaft possible

- parameters adjustable