Lubricant coolant maintenance

- without chemicals -

safe, efficient, durable

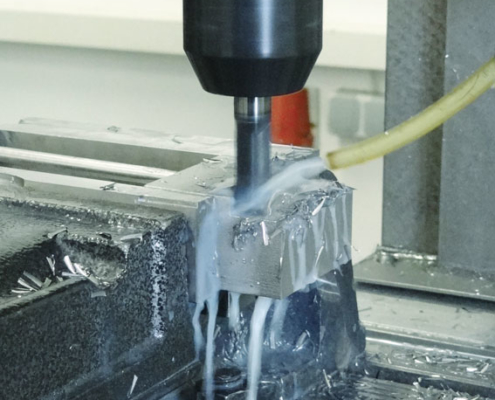

The Challenge

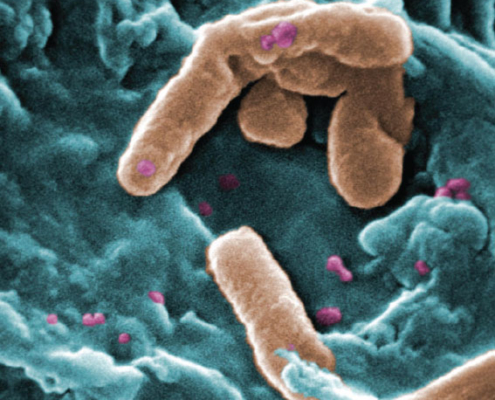

Lubricant coolants are largely used in cutting production. The addition of biocides or disinfectants is frequently necessary in order to maintain the hygiene of the coolants. By law, a risk analysis is required laying down the protective measures which must be taken to safeguard work processes and health. Good grade lubricant is the key to problem-free and superior quality manufacturing processes. Waste disposal is carried out by specialists and is a significant cost factor. Negligent handling of lubricant coolants can result in major risks for production, health and the environment.

The Solution

The Steinhardt DilliGent® CareTec uses innovative hydro-mechanical technology for the effective, environ-mentally and health-friendly treatment of lubricant coolants. Pollution is treated reliably and re-contamination prevented. Long years of experience and expertise in the field of water treatment have been invested in the development and application of DilliGent® cavitation technology. The compact units are integrated into existing machinery or the central plant and operate fully automatically with no additional chemicals.

The Way

The DilliGent® CareTec ‘s operation is based on physical active principles and is chemical-free. A partial flow of coolant passes through the DilliGent® CareTec unit for treatment. Bacteria are mechanically destroyed and removed from the water by oxidation, achieving an overall improvement in the quality of the lubricant coolant. An appropriate filtration process further increases the degree of impurity removal. Re-contamination is effectively prevented and the service life of the lubricant coolants significantly lengthened. The CARETEC unit can be exactly adapted to existing system volumes and is suitable for either permanent or intermittent operation.

The Advantages

- innovative health protection

- sustainable environmental protection

- reduces repair and maintenance periods

- chemical-free

- eliminates bacteria

- low maintenance and operating costs

- pays for itself within a short time

- robust and durable technology

- integration into all systems possible

- increases lifetime of lubricant coolants

- removes tramp oils

- improves removal of impurities

- eliminates contamination

- prevents re-contamination

- reliable hygiene for safe workplaces

Further Products

- DilliGent® LegioTec – for Legionella prevention and control

- DilliGent® WaterTec – for process water treatment

- DilliGent® CleanTec – for washing and cleaning technology

- DilliGent® ScaleTec – for stabilising the effects of scaling